Growing up with a father in the restaurant business, Joe Fresta, Jr., was naturally drawn to the epicurean world. From his vantage point as a Sicilian American on St. Louis's The Hill, a predominantly Italian community, he spotted an opportunity to fill a niche with Fresta Limoncello.

This hand-crafted, small-batch citrus liqueur currently sells in Missouri, but expanding its reach is part of Joe's plans. He shared that vision, his background, how he got started, wins and challenges, advice for other entrepreneurs, and more.

What is your background and connection to Sicily?

My great-grandparents on my father's side came from the Taormina/Catania area. They arrived through the Gulf of Mexico and into Louisiana. They had an extremely hard time being Sicilians in the South back then. So they fled north up the Mississippi River and eventually settled in the Italian section of St. Louis known as The Hill.

My father is in the restaurant business, so I grew up in and around the restaurant industry all my life. Out of college, I went to work for the Coca-Cola Company for about eight years. I learned a lot about the grocery store and on-premise beverage side of things. That experience has served me well in this endeavor.

Several years ago, I started a Facebook page called Fasebook Food Critic (with an "s" instead of a "c" because Facebook doesn't let you use their brand in page names). And I would post a lot of very enticing food picks from different restaurants around town and wherever I traveled. People loved it and would soon start calling my photos "food porn." From there, I ended up co-hosting a radio show with another Italian gentleman, Frank Cusumano, on a local sports talk radio station.

It was called The Weekly Special, where we would bring in restaurant owners and their chefs and interview them. They'd bring food into the studio, and we'd talk about the food, the industry, the history of their restaurant, and how it all got started. Listeners loved it, and it gave them ideas on where to dine that weekend. From there, the limoncello opportunity came about.

Fresta Limoncello Founder Joe Fresta, Jr.

What inspired you to create Fresta Limoncello?

I kicked around doing a beverage. I realized I didn't want to do bourbon, vodka, tequila, wine, or beer because everybody—from movie stars to professional athletes—was slapping their name on those types of spirits. Instead, given my Italian heritage, I thought I would do a limoncello. It was unique and a road less traveled.

I sat down with a distiller, and we worked out a recipe, tasting different versions. First and foremost, I wanted it to be all-natural, with no artificial color and low sugar.

If you look at Fresta Limoncello next to all the others out on the market, many of them are almost neon yellow in color. Mine is very clear. I believe Fresta is the only one that really looks like that. So people appreciate that along with the packaging, the graphics on the bottle, and the frosted bottle itself. It's definitely drawn to the eye of the consumer, enticing people to buy and try it.

I didn't want it to be overly sweet. A lot of limoncellos are, and wouldn't you know it, that's the first comment I would get from people when they first tried it: "Wow, it's not overly sweet!"

That was paramount in how I wanted the product to be. I've drunk a lot of different limoncellos, both domestically and in Italy. They're good but just too sweet, in my opinion. So people really appreciate that, and they continue to buy it.

We're going on nearly two years with this now, and it's been very successful around the St. Louis area and throughout Missouri.

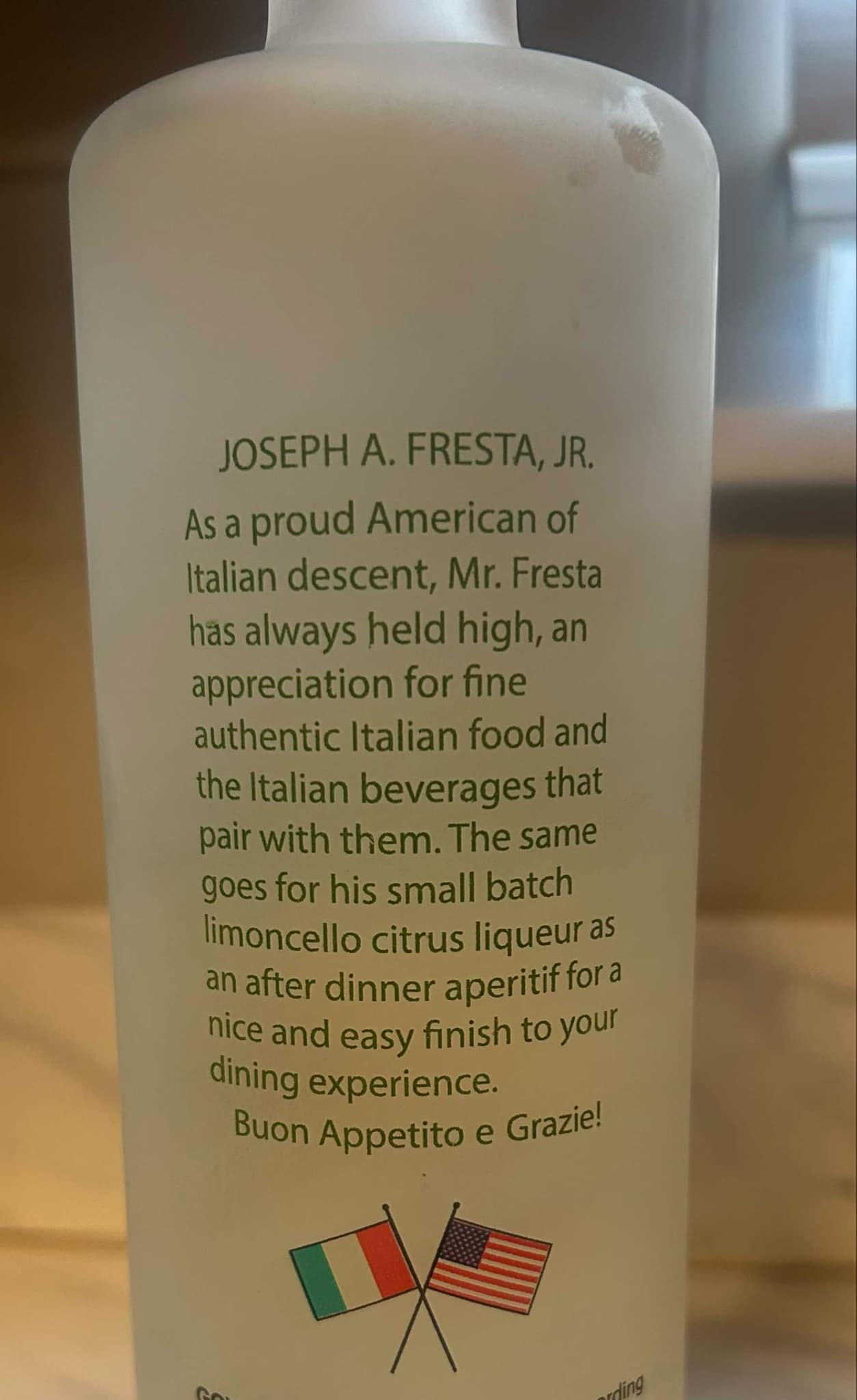

A message on a bottle.

How do you account for your success?

I do a lot of social media with photo shoots that I conduct personally. I'm very hands-on. Everything from the taste, the graphics on the bottle, and how it's marketed. Social media is a very powerful medium if you know how to use it properly, so I've really capitalized on its power. My distributor has done a pretty good job with market penetration as well.

I also get out in the marketplace. I go to restaurants to visit with owners and their customers. I have them try the limoncello and tell them where they can purchase it. That's led to us getting into all three major grocery store chains in St. Louis and around Missouri. I'll also go into the grocery stores to check shelves and front up the bottles. There are a lot of mom-and-pop Italian grocery markets and restaurants around town as well.

What challenges have you faced?

The challenge is distribution because you have to keep up with the demand. It's a good problem to have, actually. But, if there aren't enough bottles behind the bar or on grocery store shelves, I'm not going to sell product or add and keep customers.

It's been a labor of love because I've grown up in and around the business, and I've been blessed to know a lot of people in the restaurant industry. It really has been a lot of fun. I'm looking forward to keeping the momentum going, saturating the Missouri market, and then eventually moving out exponentially from the St. Louis and Missouri epicenter, getting into neighboring states, especially in cities with predominantly Italian communities and restaurants.

What feedback have you received from Missouri bars and restaurants?

They like it. How do I know that? They keep ordering it. And there are restaurants and grocery stores that just blow through it, especially during the holidays.

There's one particular Italian grocery store here on The Hill called DiGregorio's. They went through several cases of it within four hours on Christmas Eve.

A lot of companies or business owners bought Fresta Limoncello as Christmas gifts for clients and family members. They would even give me feedback on the reaction of the people they would give it to. People just loved it! Being handed that bottle and, most notably, the story behind it, and it being something local, too.

Your limoncello is award-winning. What does that mean to you and your brand?

My distiller entered the 2023 New Orleans Spirits Competition on a whim before we even hit the marketplace. It won the silver medal in the Liqueur Category. Getting that kind of an award or recognition early on meant a lot. It provided a lot of confidence in the brand and, more importantly, the actual product itself. It certainly gave me an initial selling point when I first started going around and trying to introduce people to the product. It provided a solid platform to walk into an establishment and say, "Hey, look, we won this award," and I incorporated that into a lot of the social media as well. It was a major positive.

Fresta Limoncello is sold throughout Missouri.

What are your future plans?

The next step would be to do a pre-packaged Fresta Spritz, which would be pre-made with a Prosecco in four-pack glass bottles.

We may also do a Fresta Limoncello La Crema. One of those two things will likely be the next step from the flagship.

What impact do you hope to have on the St. Louis community?

I do a lot of charity work. I am a two-time cancer survivor and the Board Chair of the Cancer Care Foundation I founded. It's about 13 years old now, and I've raised over $2 million for families who are fighting cancer. So, at some point down the road, when the brand becomes more successful, I would like to incorporate that into my cancer foundation and help raise more funding to help cancer patients pay their bills and whatnot.

What advice would you give someone looking to start a spirits brand?

Find a niche market like I did. Take an avenue that's less traveled and where you can be the father of that, and just go for it. Surround yourself with the right people. Don't let anybody tell you "No" or "You're crazy for doing it." Just go ahead and get in there!

After the demise of Anheuser-Busch in St. Louis, when the Busch family sold out, a lot of microbreweries started to pop up all over the place, and those guys did a pretty good job of filling a void and being pretty successful in their own right.

What experience do you hope to share?

I would just share with people the importance of great customer service. I think it's a dying component in the service industry today. I want my customers to know we're there for them when they need something. It all comes down to service. You've got to take care of the customer.

If you enjoyed this article, consider subscribing to my newsletter for more content and updates!